LB-PP/PE Khadka Mishiinka Goynta Goynta Biyaha Hoostooda

| Qaabka | LBUW-40 | LBUW-50 | LBUW-60 | LBUW-70 | LBUW-80 | LBUW-90 |

| Moodeelka Iskoolada | 41/24-80:1 | 52/24-80:1 | 62/24-80:1 | 71/24-80:1 | 81/24-80:1 | 93/24-80:1 |

| Qaadashada (kg) | 130 | 250 | 400 | 500 | 800 | 1000 |

| Awoodda Matoorka (kW) | 37 | 75 | 110 | 160 | 250 | 315 |

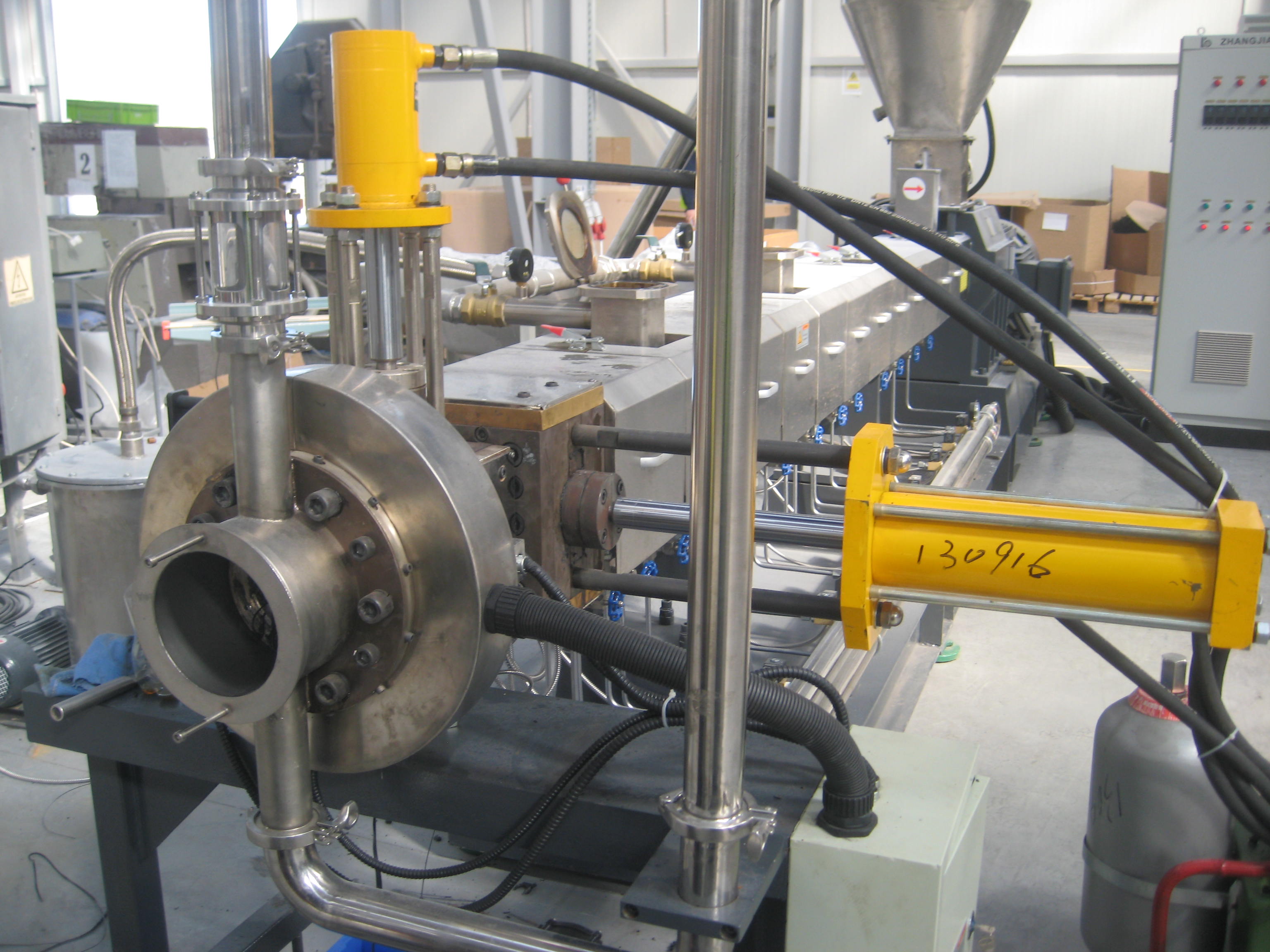

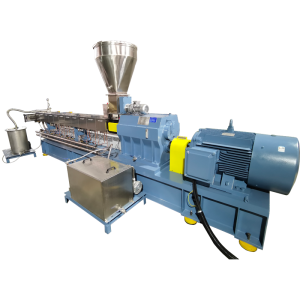

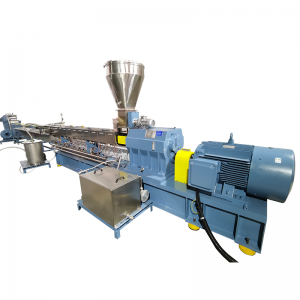

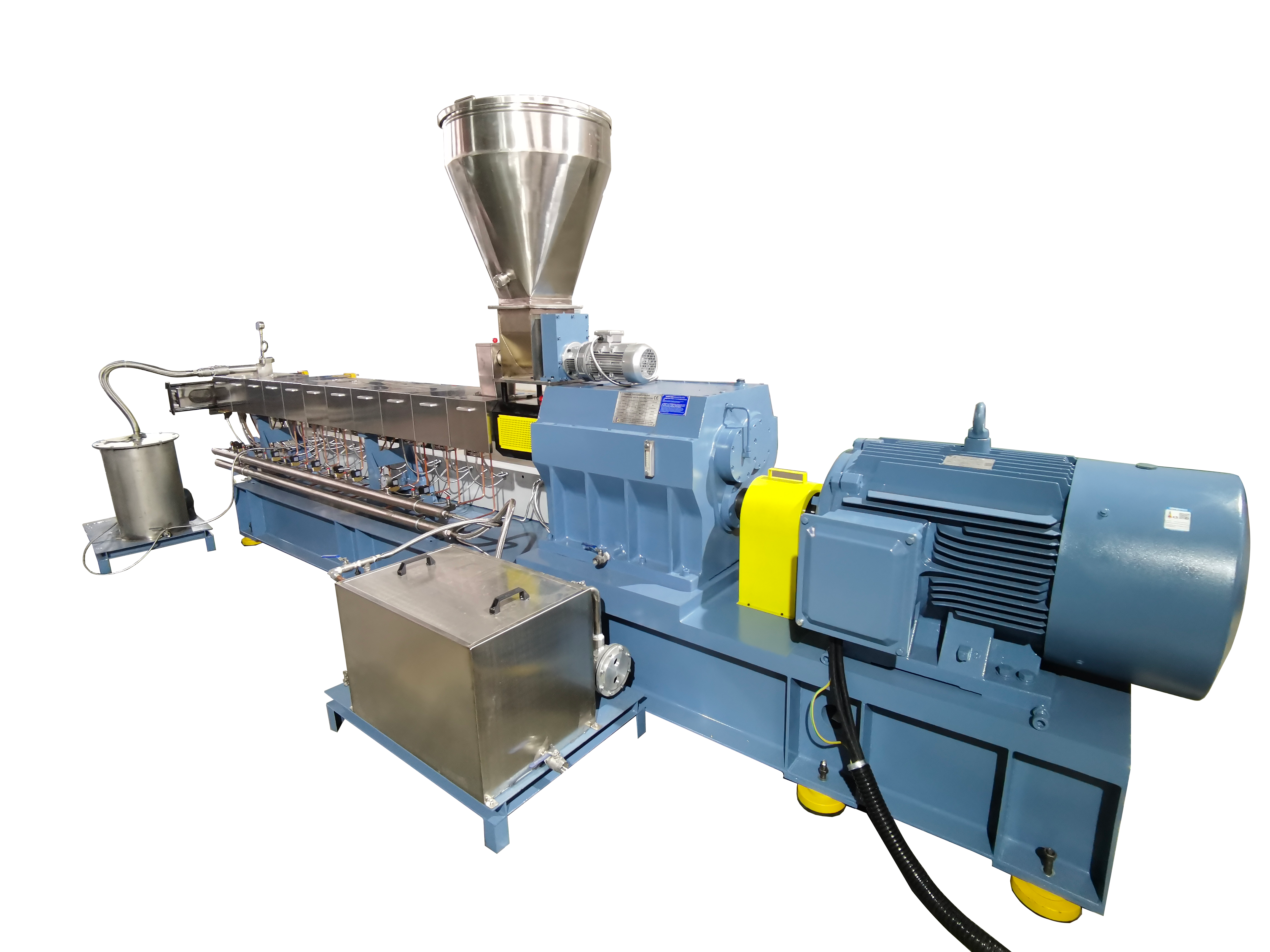

Isbarbar yaaca Twin Screw Extruder

Iyada oo ku saleysan qorshaha wax-soo-saarka la habeeyey, waxaanu leenahay fikrado extrusion kala duwan oo doorasho ah. Isbarbardhigga Twin Screw Extruder wuxuu ku salaysan yahay waayo-aragnimadeena inta badan xalinta dareeraha, kaas oo ku daraya qalabka granulating biyaha hoostooda.

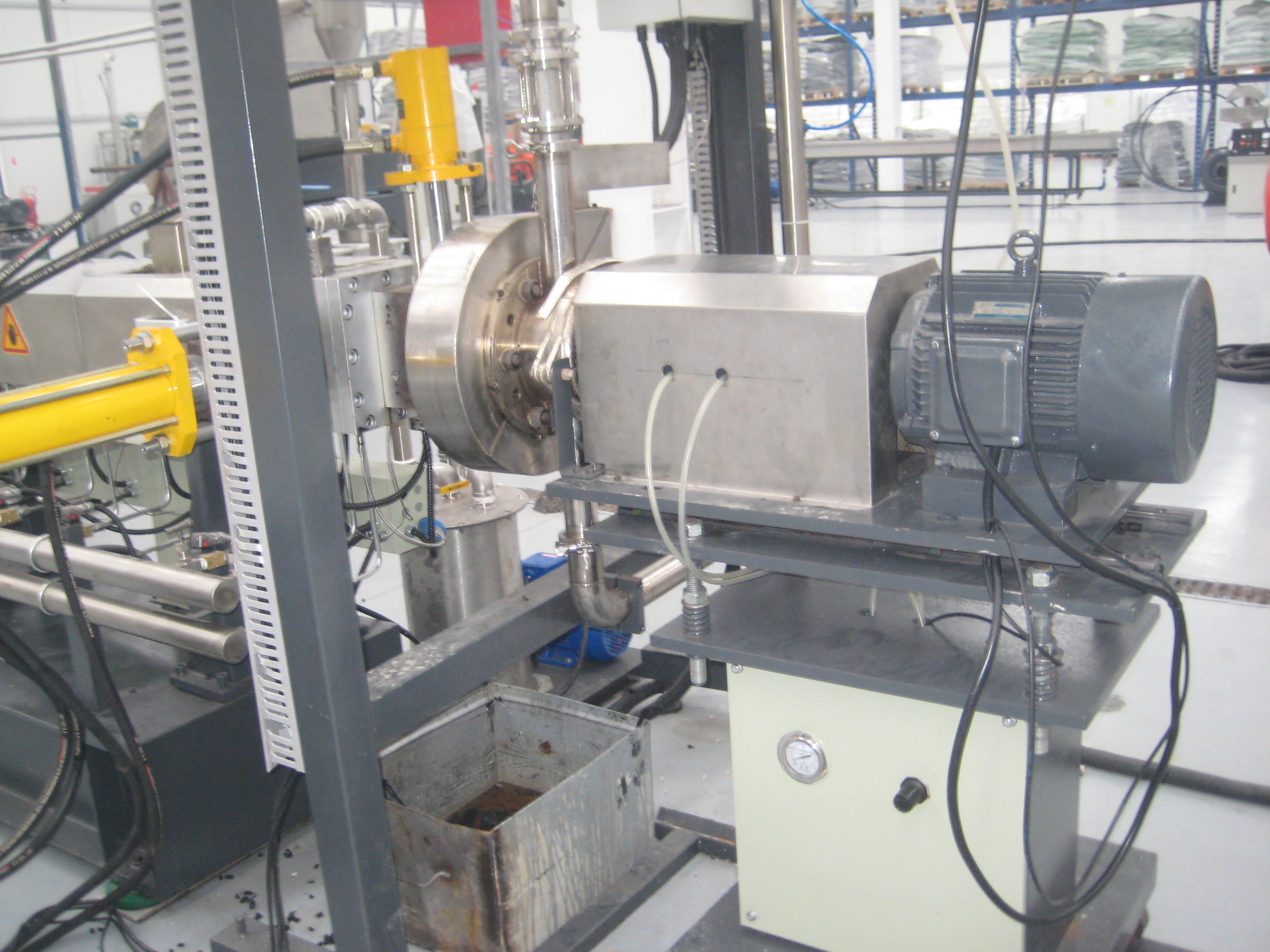

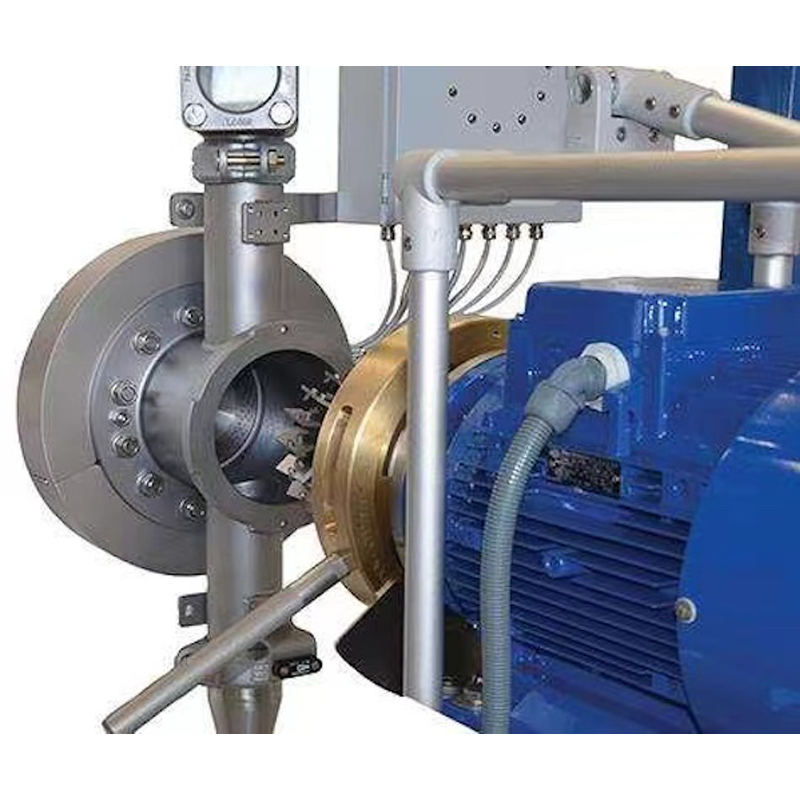

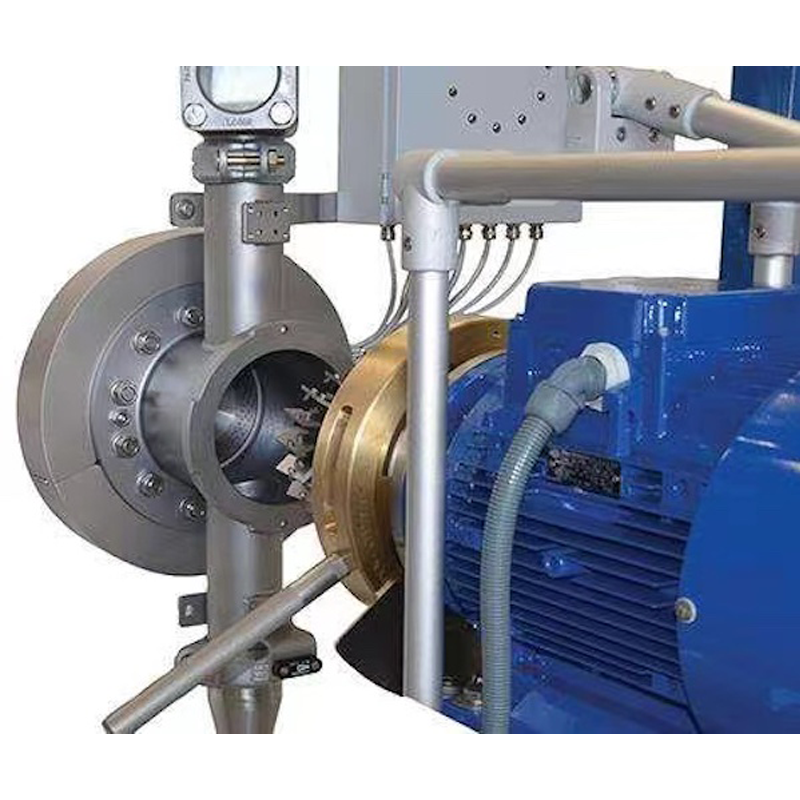

Shaashada beddelka

Beddelaha shaashada waxa loo isticmaalaa nadiifinta wasakhda dhalaalaysa (ciid, bir, balaastiig kala duwan) kuwaas oo hoos u dhigaya tayada granules. Waxaa jira noocyo kala duwan oo ah beddelayaasha shaashadda sida hal-ama laba-taarikada beddelka shaashadda iyo beddelaha shaashadda hal-ama laba-dhululubo. Iyada oo ku saleysan xaalad shaqo oo kala duwan, beddelka shaashadda ku habboon ayaa la qaadan doonaa.

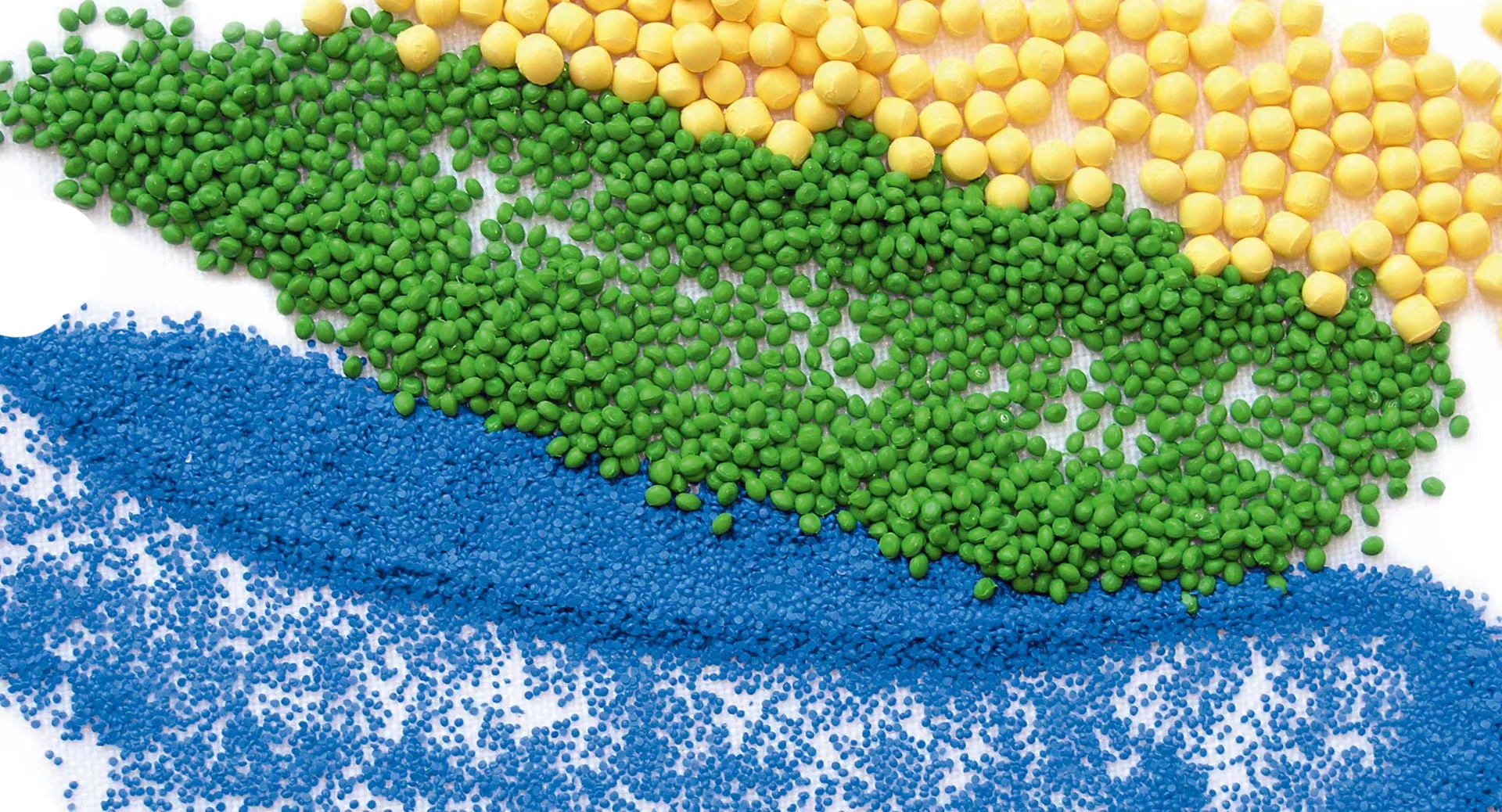

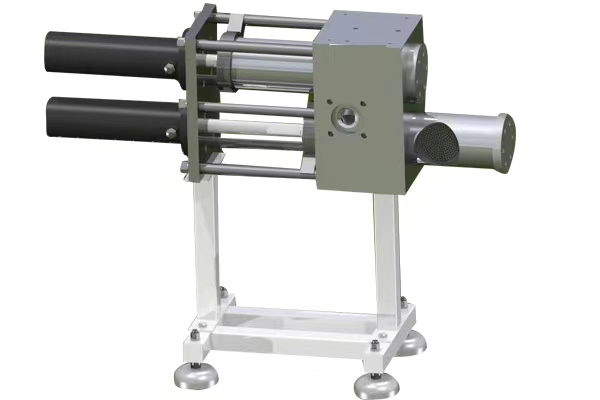

Nidaamka Granulating ee biyaha hoostooda

Sii wadcadaadiska u dhexeeya mindida wareega iyo wejiga dhinta waxaa lala socdaa waqti goynta dheer iyo tayada sare ee granules. Xawaaraha wareegga mindidu wuxuu ku salaysan yahay cadaadiska dhalaalka oo si toos ah ayaa loo hagaajiyaa. Qalabka mindida rotary waa la hagaajin karaa si loo dayactiro. Beddelka fudud ee mindiyaha waxay badbaadisaa wakhtiga dayactirka.

Wareejinta sentifugal

Waxay kala saartaa granules iyo biyaha. Granules-ka waxaa laga soo qaadi doonaa qalajinta centrifugal ee xagga hoose ilaa sare ee aaladda debiyaha. Inta lagu jiro qaadista qoyaanka si wax ku ool ah ayaa loo dhimi doonaa.

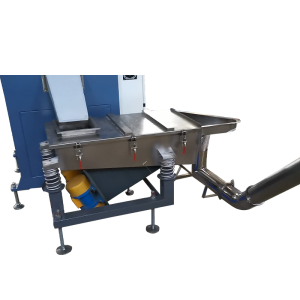

Vshaandho ibration

Tshaandhada gariirku wuxuu shaandheeyaa granuleska oo leh cabbirkiisa. Granules aadka u weyn ama yar ayaa sifeyn doona. Kaliya cabbirka saxda ah ayaa lagu rari doonaa seeraha kaydinta.

Kaydinta Silo

Granules-ka ugu dambeeya waxaa lagu kaydin doonaa silo. Iyada oo ku saleysan baahida nidaamka kormeerka iyo miisaanka on-line ayaa lagu dabaqi karaa.